Index

How to polish your car

INTRODUCTION

In the last guide we’ve talked about car polishing, discovering all the benefits of this working process, that are not only related to the car aesthetics (did you lose the last guide? Look here.)

Today we’ll deal with the practical aspects of polishing. We’ll talk about the necessary equipment, and how to choose it at best. After that, we’ll see how to polish the car body.

Have you lost the previous tutorial?

WHAT YOU NEED

First, remember that the necessary step before starting polishing is the car body decontamination (we’ve talked about it in our first guide). After that, we can start the polishing process. The necessary equipment is:

Polishing compounds

During the article, we’ll discover that every situation may need a different compound.

Pads for polishing

Pads can be of different materials. The most common are Foam pads and Wool pads. PaiCar range offer both these types.

Polishing machine

The polishing machine can be a rotative or a roto-orbital one, depending on the type of work, and on the operator’s preferences.

Backplate

It’s the accessory that allows to adapt the pad to the polishing machine.

Surface’s cleaner

(optional but recommended)

Microfiber cloths

(optional but recommended)

CHOOSING THE RIGHT COMPOUNDS AND ACCESSORIES

Let’s proceed discovering how you can choose the best equipment for the car polishing.

Polishing compound choice

This important choice depends on the damages on the car body. The heavier the defects are, and the more the compounds must be abrasive, to remove them. The use of a hard-cutting polishing compounds leaves marks and swirls on the surface (the “polishing marks”). For this reason, often a polishing process is formed by two or more steps: after the firs abrasive step, is needed to use a polish, that can remove holograms and polishing marks, leaving a refinished car body.

Another important factor of choice is the final glossy level desired. In some cases, operators prefer to reduce working time, using a “one step” compound. This type of product combines a high cutting power with a good gloss capacity. In this way, it’s possible to remove damages from the car body and obtain an acceptable gloss level, using a single product. Instead, if the final desired result is an high gloss level, a 2 or more step process is needed.

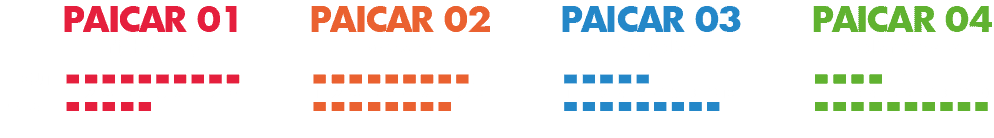

Does that seem like a difficult choice? To simplify the decision process, PaiCar has developed a lean but complex range, composed by 4 polishing compounds. For every product, our team has studied and indicated the “cut” (abrasive power) and the “gloss” levels.

The choose of the pad

The right pad can increase the polishing compound performance until 30%! For this reason, you need to pay attention in the making of this choice.

As we already said, there are wool pads and foam pads.

The wool pads perform a more abrasive action compared to the foams. There are more adapt for the first step on the car body polishing. Our SL3 fine wool pad can be choose when you’re using PAICAR01 or PAICAR02. It’s good balanced between cut and sensitivity.

The foam pads can be used in every polishing step. In this case, it’s important to pay attention to the consistency of the foam. The hardest ones, like DA-01 or DA-02, are indicated for the first step. The softer ones, like DA-03 or DA-04, have been developed for the refinishing phases.

To make the choice easier, PaiCar range matches the foam colours with the right compound’s label.

We’ll deepen the pad’s question in the next guides, when we’ll talk about the main differences between foam and wool pads.

The choice of the polishing machine.

Regarding the polishing machine, every operator has his preferences. We can say that the rotative polishing machine is adapt only for the first steps, when the abrasive power must be higher. While the roto-orbital one, when matched with the right foam pad, can be useful for every polishing step.

The choice of the backplate

The backplate is needed to adapt the pad to the polishing machine. This is another choice that may depends on the operator’s preferences. For instance, the S10 rubber backplate is flexible, and it’s able to adapt on every corner of the car body. It’s particularly effective in the absorption of the machine’s vibrations, allowing the operator to avoid tiring his arm.

The S15 backplate has a foam interface, which makes the polishing process even more comfortable. It’s been developed specifically to match with the DA foam pads, and to help the air circulation (we’ll talk about the DA system in the next guides).

HOW TO POLISH YOUR CAR

After a correct car body decontamination, we can choose the right compounds with the combined accessories and start the polishing process.

Before turning on the polishing machine, it’s important to cover the areas that will not be subject to processing, to avoid damages creation We’re talking about seals, emblems, headlight, bumpers. It will be enough to use the adhesive tape, to separate the car body from these components.

The chosen pad must be adapted to the polishing machine through the backplate. It’s important to precisely center the pad on the backplate, because the backplate mustn’t enter in contact with the car body surface to avoid the damages creation during the working process. For this reason, the backplate surface is ever smaller than the pad diameter. For example, normally a 150 mm backplate is indicated for a 175 mm pad.

Proceed applying some compound’ drops on the pad and, with the polishing machine switched off, spread it on the surface using the pad.

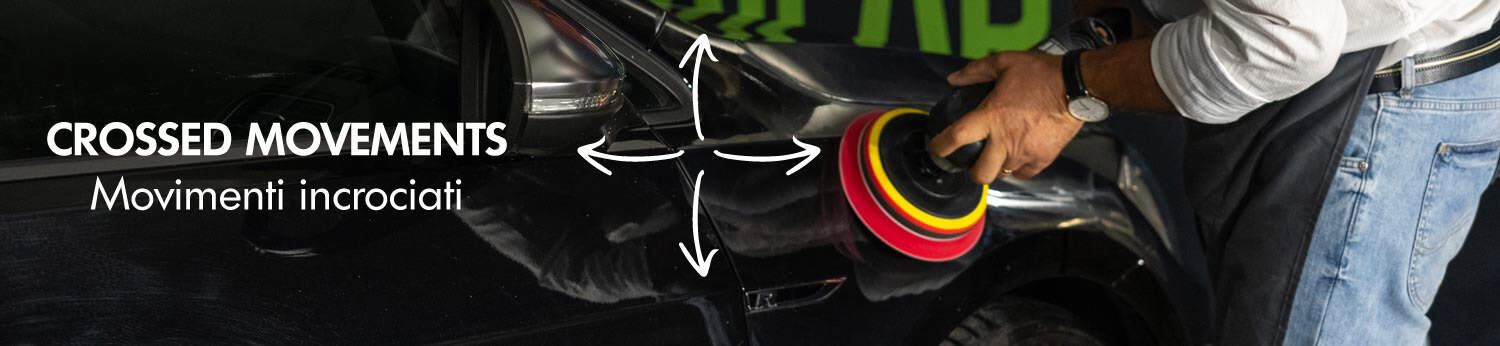

Gradually increase the speed of the polishing machine. Proceed working slowly on the surface. Never stay still on a point but keep moving. It’s suggested to use crossed movements, going from left to right and up-down, always moving few centimetres a time.

Place yourseld so that you can precisely look at what you’re doing. Otherwise, you might work badly. Keep your eyes in the near of the surface, possibly backlight. When you’ve completed to spread the compound, turn off the polishing machine and clean up the surface using a microfiber cloth, like one of our Silky-Tech. Let’s proceed on this way on all the interested area. Remember to restrict processing on a 60×60 cm area a time.

CONCLUSION

To correctly polish your car, it’s necessary to previously choose the right compounds and accessories. As we said, different situation may require different products combination. So, the important point is to choose the right combination for your case. To obtain that, you need to take the necessary information, and decide which products are more suitable.

Car polishing requires particular attention in the working process. Both the decontamination phase and the polishing process need to be done paying much attention to the details, because be distracted could cause damages creation on the surface.

At least, car polishing is funny and satisfying! If the job is done following these practical suggestions, you will obtain an enviable car body.

We hope you good polishing.